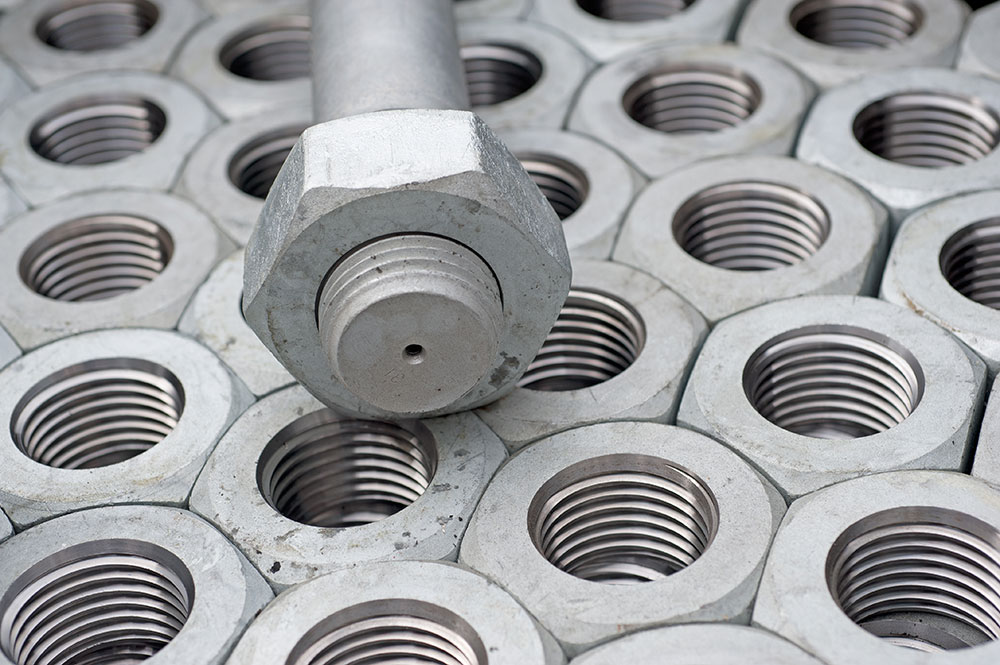

STOCK STUDBOLT ASSEMBLIES AND SPECIAL FASTENER MANUFACTURING

- Experts in end-user vendor lists and strict origin restrictions.

- Fast turnarounds and time-sensitive deliveries.

- Small-batch specials and high-quantity production.

- Manufactured according to international standards and customer drawings.

- Hard-to-find materials, unusual dimensions and thread-forms.

- Shipping via courier, airfreight and ocean-freight.

- Fully traceable products and all levels of certification, testing and third-party inspection available.

Whether your requirement is for urgent critical maintenance, an upcoming shutdown or you have plenty of time to plan, PPML Bolting ensure your materials are delivered exactly when you need them.

OUR PRODUCTS

MATERIAL GRADES

ASME SA / WERKSTOFF / EURONORM EQUIVALENTS OF ASTM GRADES AVAILABLE, INCLUDING METRIC STANDARDS. BAR AND FORGING DESIGNATIONS AVAILABLE ACCORDING TO REQUIREMENTS.

COMMON NAMES INCLUDE: DUPLEX, SUPER DUPLEX, ALLOY C276, NICKEL 200, ALLOY 400, ALLOY 600, ALLOY 625, ALLOY 20, ALLOY 800, ALLOY 800H/HT, ALLOY 825.

TRADENAMES INCLUDE: SAF 2205®, SAF 2507®, ZERON®, FERRALIUM®, HASTELLOY®, MONEL®, AL6XN®, NITRONIC®, NIMONIC®, INCONEL® AND INCOLOY®.

OTHER GRADES AVAILABLE UPON REQUEST.

ANCILLARY OPERATIONS AND SERVICES

We offer an extensive range of coatings and surface treatments to inhibit corrosion, extend fastener life and aid with assembly/disassembly. Coatings include hot-dip-galvanisation, zinc, zinc-nickel, cadmium, chrome, silver, anodising, PTFE, ceramic and special coatings. Tradenames include Xylan®, Xylar®, Sermagard® and Deltatone®.

We specialise in the reverse engineering of customer parts where the material is unknown and there is no drawing or specification available but a like-for-like product is required. This is especially useful when refurbishing existing equipment where the original manufacturer no longer exists. Speak to our team to find out more about the process.

We manufacture to all major end-user material and testing specifications. Product is fully tested and certified to requirements and delivered with the necessary paperwork such as databooks, Inspection Test Plans, accelerated weathering tests, inspection and sampling reports.

For projects requiring bolt tensioning and assembly services or a specific type of tension-indicating feature then we can help. We work closely with our expert bolt tensioning partners to offer turnkey solutions.

- BS EN 10204 2.1, 2.2, 3.1

- BS EN 10204 3.2 Third Party Inspection

- Raw Material Certification

- Mechanical and Chemical Analysis

- Low Temperature / Cryogenic

- Accelerated Weathering: Salt-fog and UV

- NDT: PMI, MPI, DYE-PEN, UT, DIMENSIONAL

Visit our Quality page for more information